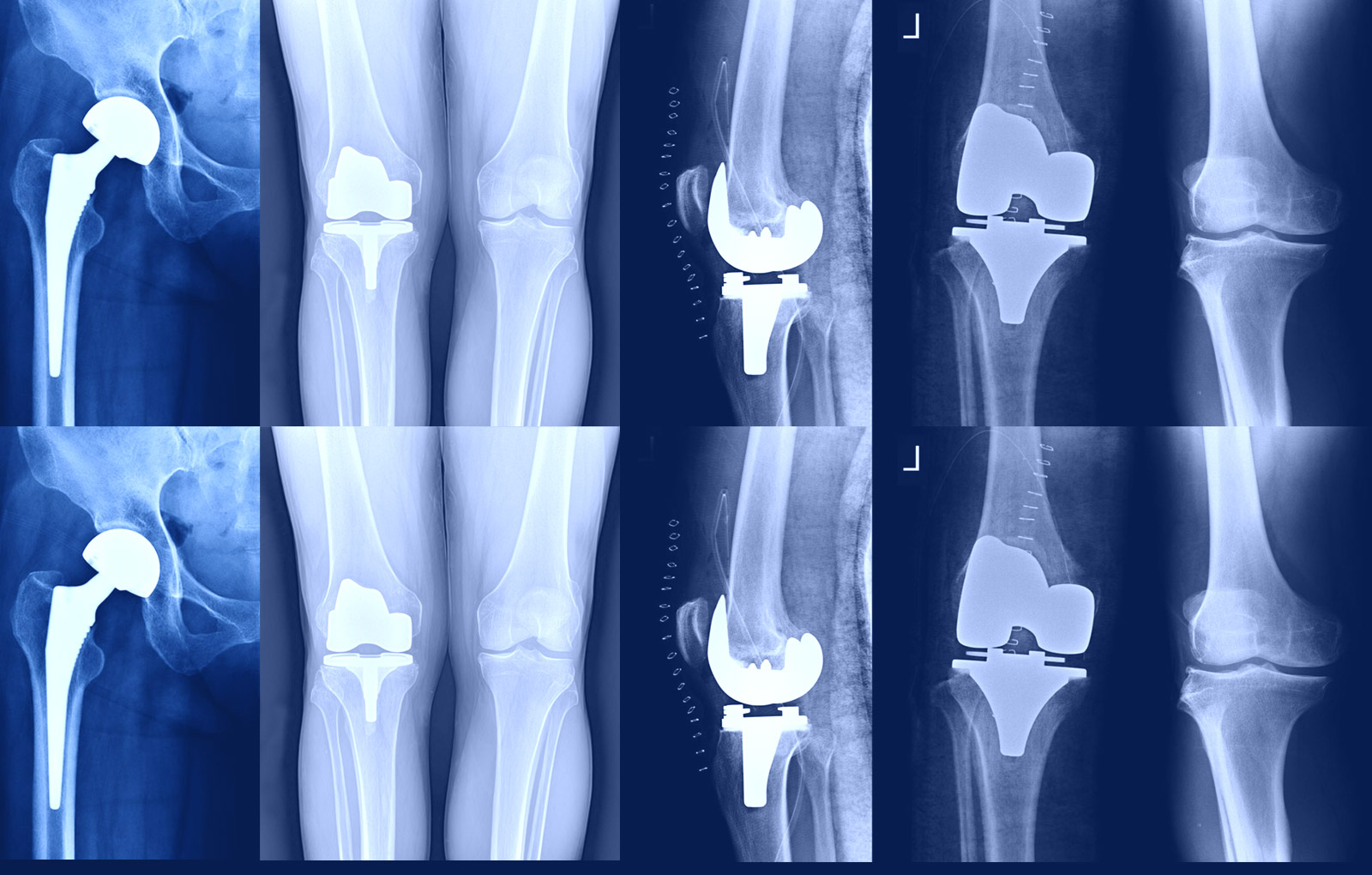

Total Hip Replacement System

Cemented stems in hip replacement surgery have been in use since the pioneering years of Sir John Charnley.

The polished dual-tapered LATITUD stem is based on the highly successful loaded taper principle with biomechanical characteristics that have been proven over more than three decades of successful clinical use.

- The fully modular system allows the surgeon to select the implants which best meet the patients clinical needs

- Versatility of the system allows for easy conversation to a total hip construct shoul this be required intra or post operatively

- Easy to use effective instrumentation designed to enhance clinical outcome

- Available in stem sizes, designed to ensure optimal match to patient’s anatomy

| Std. Stem | Size | Offset | Neck Lenght | Stem Length |

| Std. Stem | T-Loc Stem Standard Size 00 | 37.0 | 36.10 | 127 |

| Std. Stem | T-Loc Stem Standard Size 1 | 45.0 | 40.56 | 149 |

| Std. Stem | T-Loc Stem Standard Size 2 | 45.0 | 40.56 | 149 |

| Std. Stem | T-Loc Stem Standard Size 3 | 45.0 | 40.56 | 149 |

| Std. Stem | T-Loc Stem Standard Size 4 | 45.0 | 40.56 | 149 |

| Narrow Stem | T-Loc Stem Narrow Size 1 | 38.0 | 38.20 | 149 |

| Narrow Stem | T-Loc Stem Narrow Size 2 | 38.0 | 38.60 | 149 |

| Narrow Stem | T-Loc Stem Narrow Size 3 | 38.0 | 38.60 | 149 |

| Narrow Stem | T-Loc Stem Narrow Size 4 | 38.0 | 38.60 | 149 |

Uncemented Stems

The design philosophy for Cement less femoral stem of latitud total hip replacement system is adopted from well proven and successful corail stem design. Cement less femoral stem is provided in two different angles to meet with patient’s anatomy and developed into two versions: standard and increased offsets. The surface of cement less femoral stem is coated with hydroxyapatite with plasma spraying method for osteo-integration purpose and to be used without cement. The Dual Taper Trapezoidal Design with vertical and horizontal grooves to promote stability and resist rotational and axial displacement.

The low modulus of elasticity of titanium reduces the mismatch with the cortical bone and reduces thigh pain.

Features

- The Uncemented femoral stem is made from Ti-6Al-4V ELI alloy as per ASTM F136 Standard Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant Applications.

- Stem is coated with Osprovit® Hydroxyapatite by plasma spraying method in compliance with ISO-13779-2/ BS ISO 13779-4 below the resection line.

- Porosity of coating is maximum 10% and surface roughness value for HA coated surface of uncemented femoral stem is above 30 μm with adhesion strength above 15 MPa.

- The Uncemented femoral stem is straight and tapered with a lateral chamfer to aid insertion.

- It has both vertical and horizontal grooves to resist axial and torsional loading.

- Uncemented femoral Stem neck is having a 12/14 taper trunnion for connection with femoral head.

- It is available in 11 different sizes with Provision of 135o standard, 135 lateral, 125 Standard (coxavera) neck angle and polished distal section

- Low profile polished neck increases the head-neck ratio, reducing impingement and increasing the range of motion for the patient

- Low profile shoulder is bone conversing in the greater trochanteric region and allows for ease of us in smaller incision surgery

- Metaphyseal flare ensures maximum fixation and load transfer into the proximal femur

- Horizontal grovees in the proximal stem, supported by dense cancellous bone, provide axial stability preventing subsidence

| Sizes | |||||

| Comes in 135 neck angle | (0 size to 10 size) | ||||

| High offset 135 neck angle – Used for lateralization and extreme morphologies |

(0 size to 10 size) | ||||

| Coxa vara 125 neck angle – Used for Coxa vara indications and lateralisation defects |

(0 size to 10 size) | ||||

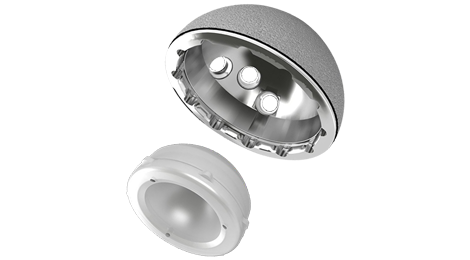

Bi-Polar Cup System

Bipolar Cup is an alternative to total hip arthroplasty, particularly indicated in the treatment of displaced femoral neck fractures in elderly patients.

Bipolar Monoblock Cup

The Bipolar Monoblock cups is comprised of an outer Stainless steel metal dome, an inner liner of Ultra high molecular weight polyethlene. Bipolar Monoblock cups has the following basic design features: The metal dome of Bipolar Monoblock cups is fabricated from the stainless steel 316L. It consists of an outer metal surface of stainless steel 316L designed to articulate directly in the patient acetabulum by press fit with surface roughness Ra= 0.05 μm. It has an inner ultra-high molecular weight polyethelebe (UHMWPE 1050) surface which is assembled during manufacturing. Modular femoral head will articulate in liner. Surface roughness of this articulating surface is Ra= 0.05 μm The Modular head will be assembled in biploar cup by surgeon during implantation and intended to be used with femoral stem.

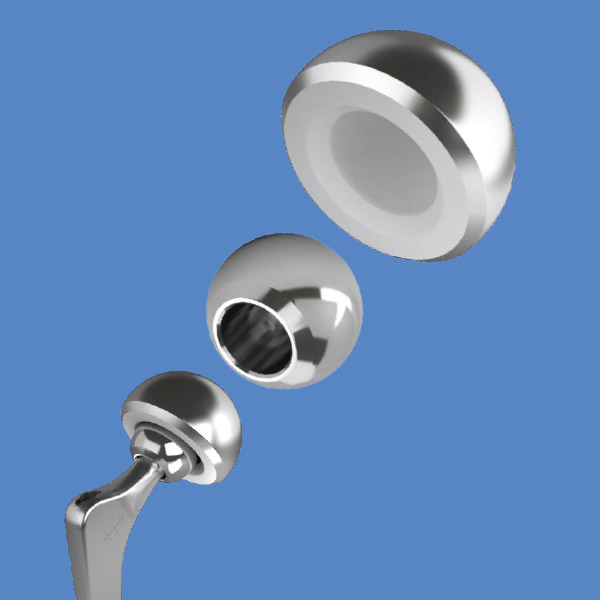

Femoral Stem System Modular femoral head

Modular head is designed to mate with 12/4 taper of femrol stem through taper-locking arrangement and to be articulated with Modular Liner.

Modular heads are manufactured from High Nitrogen Stainless Steel as per ISO 5832-9.

Available in 5 sizes ranging from diameter (ø) 22 & 28mm with different offsets viz. +0.0, +3.5, -3.5, +4.0, -4.0, +7.0. Surface roughness value of outer articulating surface is Ra= 0.05 μm.

The Bipolar Monoblock shell is available in 21 different sizes ranging from 37 to 63mm. 37 to 51mm in 1mm increment and from 53 onwards in 2mm increament.

Bi – polar & modular Head Compatibility

| Sr. No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 |

| Bi-polar Cup Size | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 | 51 | 53 | 55 | 57 | 59 | 61 | 63 |

| Modular Head | 22 | 22 | 22 | 22 | 22 | 22 | 22 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 | 28 |